Particle accelerators are used in some of the most cutting-edge research imaginable, but researchers don’t always have access to the most state-of-the-art versions of the technology.

By making particle accelerators smaller and more affordable, Austin startup TAU Systems plans to be the first company to sell this technology as a commercial product. It will also offer particle accelerator-based research and data analysis as a service, democratizing access to researchers in medicine, chemistry and other fields.

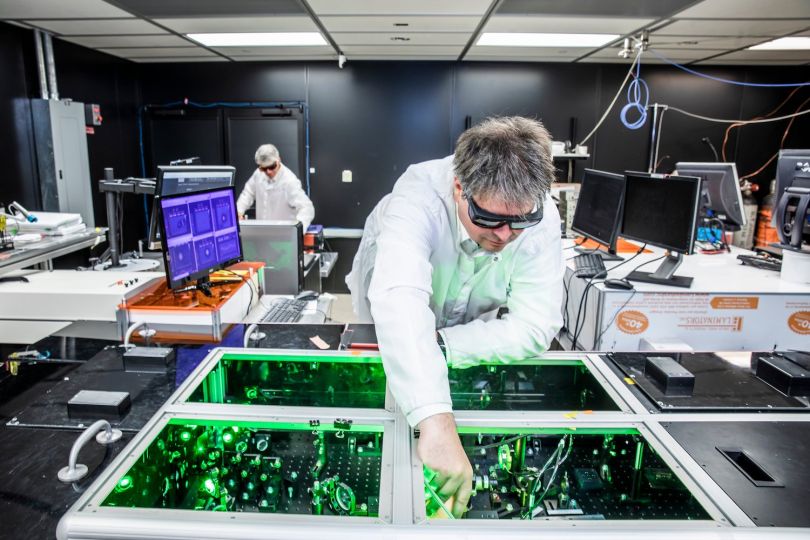

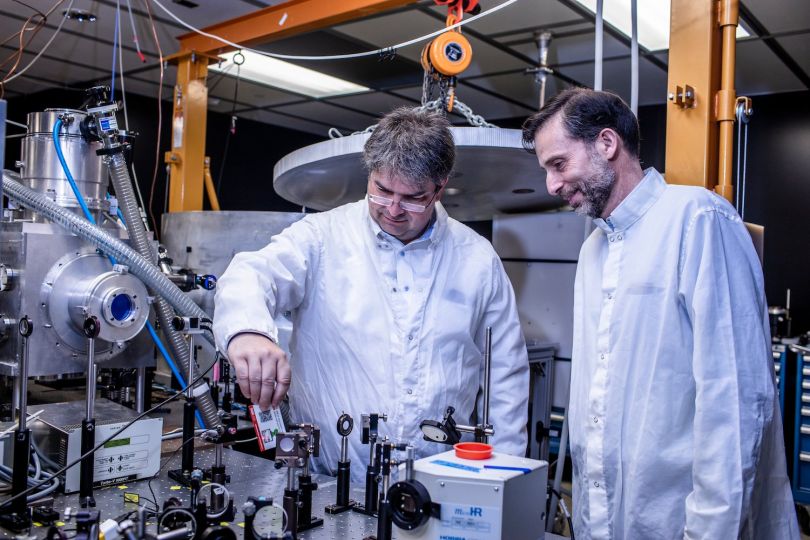

TAU spun out of the University of Texas at Austin, where Professor Bjorn Manuel Hegelich and his team developed a prototype of a laser-driven particle accelerator. The company currently has 15 employees, some of which live in California.

With $15 million in seed funding from entrepreneur Lukasz Gadowski, TAU will work toward the development of an industrial prototype. The company is negotiating with several institutions as to where that work will occur.

Particle accelerators speed up subatomic particles like protons and electrons, creating beams of supercharged particles. Traditionally, accelerators are metal structures that are driven by radiofrequency waves. TAU, on the other hand, accelerates and charges subatomic particles by directing lasers at plasma. This technique allows for much higher intensities because it does not have the material limitations of metal.

“You have a solid that you melt into a liquid, and if you heat it more, it turns to gas. If you keep heating it more, you now start ripping the electrons off the nuclei and you have a plasma,” Hegelich said. “Basically, once you have a plasma, you have done pretty much all the damage you can possibly do to it. There is no way to damage it more than that. This is why, in a plasma, we can support accelerating fields that are 1,000 times, a million times stronger than what you can support in a metal structure. Since our field is 1,000 times stronger, the distance we need to get particles to the same energy can be 1,000 times shorter.”

One of the most well-known accelerators in the U.S., the Stanford Linear Accelerator, was two miles long and could generate 50 gigaelectron volts [GeV]. TAU’s accelerator, meanwhile, is only 10 meters long and generates one GeV per centimeter.

Stanford discontinued its linear accelerator in 2016 so researchers could focus on its LCLS-II X-ray laser. Hegelich said the LCLS is the only particle accelerator of its kind in the U.S., making it difficult for researchers to get access to it.

“Until now, the world’s most powerful accelerators have simply been too large and too expensive to be a realistic tool for the vast majority of scientific and corporate users,” Hegelich said in a statement. “We believe that access to our machines will have transformative impacts across almost every industry and the economy.”

TAU has the capability to produce laser-driven accelerators that could be as small as a desk or as large as 20 to 30 meters, Hegelich said.

The accelerators can produce X-ray free-electron lasers (XFEL), which allow researchers to examine materials on the molecular or atomic level. XFEL technology could be used to develop longer-lasting batteries, determine how photosynthesis works or develop the next vaccine or pharmaceutical drug, Hegelich said.

“By taking these machines and making them smaller, cheaper and more available, it kind of democratizes particle accelerators and the X-ray sources and light sources they enable so that other people, universities and companies can use them,” Hegelich said.

TAU is currently using XFEL technology to analyze the quality of metallic body implants and is developing 3D medical imaging technology that has the image quality of a CT scan without radiation.

Hegelich said he hopes to have an industrial prototype of the laser-driven particle accelerator manufactured by next summer, with the first stage operational by the end of next year.

TAU expects to start selling its laser-driven particle accelerator products in 2024. In addition to selling laser-driven accelerators and XFEL systems, TAU will also offer researchers access to the industrial-level machine, at a location yet to be determined, and allow companies to pay for XFEL research and analysis.

“You can send our sample to us and we will measure what you need to be measured and then send you the data,” Hegelich said.

Once the accelerator prototype has been created, TAU will begin constructing an XFEL service center for research and data analysis, which is expected to be operational by 2026. The construction of the service center would require $50 million to $100 million in funding, Hegelich said. TAU expects to start selling full XFEL systems by 2027.